We're better together

How we collaborate

News

Date published: 16 | 11 | 16

Niaga®, a joint venture at DSM, today announces that its Niaga® technology is ready for commercial-scale production of recyclable carpets. All carpets made with this technology can be 100% recycled and made into new carpets of the same volume and quality, again and again. To boost innovation and collaboration with the carpet industry, Niaga® will extend its Niaga® Innovation Center activities and install its own Niaga® technology carpet line in Geleen, the Netherlands, as of January 2017.

Annually, around 4.5 billion square meters of carpet, tiles and rugs is fitted in buildings, cars, planes and many other interiors worldwide. Each year, billions of kilograms of carpet are discarded as landfill or incinerated. For forty years, the combination of many materials, including latex adhesive, has made it both technically difficult and economically uninteresting to attempt to recover materials for re-use.

Niaga® is convinced that its innovation has the potential to radically improve the use of materials in the carpet industry and to be instrumental to the sustainable production and re-use of carpet material on a global scale. The innovation center will serve the carpet industry to test and further develop Niaga® technology and expand their portfolios with more sustainable, reusable products. Niaga® has the ambition to make the technology available for all carpet producers globally. Together with its strategic partner Lacom GmbH, a global leader in laminating and coating machines, Niaga® has made machine sets fit for Niaga® technology.

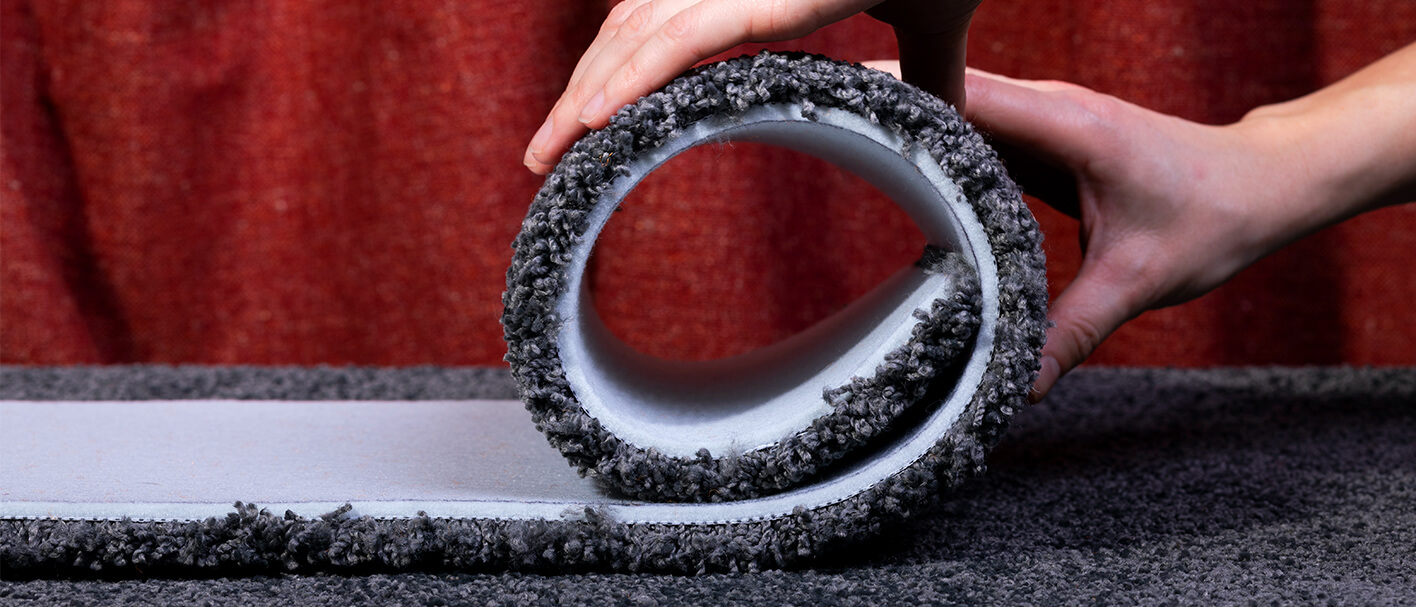

Niaga® has invested several million euros to develop a completely new technology to make circular products, starting with carpet. Niaga® partnered with Lacom GmbH, to develop a commercial-scale laminating process based on the Niaga® technology. This new laminating process enables the production of a polyester mono-material carpet, and a duo-material carpet with a polyester backing and nylon or woolen face fibers. All materials in these carpets can be recovered after use, and made into carpet, again and again. The machine uses up to 95% less energy than mainstream lamination processes and reduces water use to zero. Unlike a regular carpet, a carpet made with Niaga® technology does not contain any latex, PVC, or bitumen.

Up to now, Niaga® has tested its adhesive R&D and application solely in its Zwolle tech center. With the expansion of Niaga®’s Innovation Center activities, the company will add development capacity by tapping into the innovative knowledge and expertise of DSM’s Materials Center in Geleen - a materials powerhouse. Combining the R&D capabilities of two of DSM’s materials knowledge centers in Zwolle and Geleen, the Netherlands, makes a powerful platform to deliver on the successful growth strategy of Niaga®.

Niaga® also expects to benefit from its proximity to the center court at Brightlands Chemelot Campus in Sittard-Geleen in the Netherlands. The center court is the newest addition to the Chemelot campus where top knowledge institutions and companies, amongst others DSM’s Innovation Center, are gathered under one roof in the heart of Europe’s materials knowledge area.