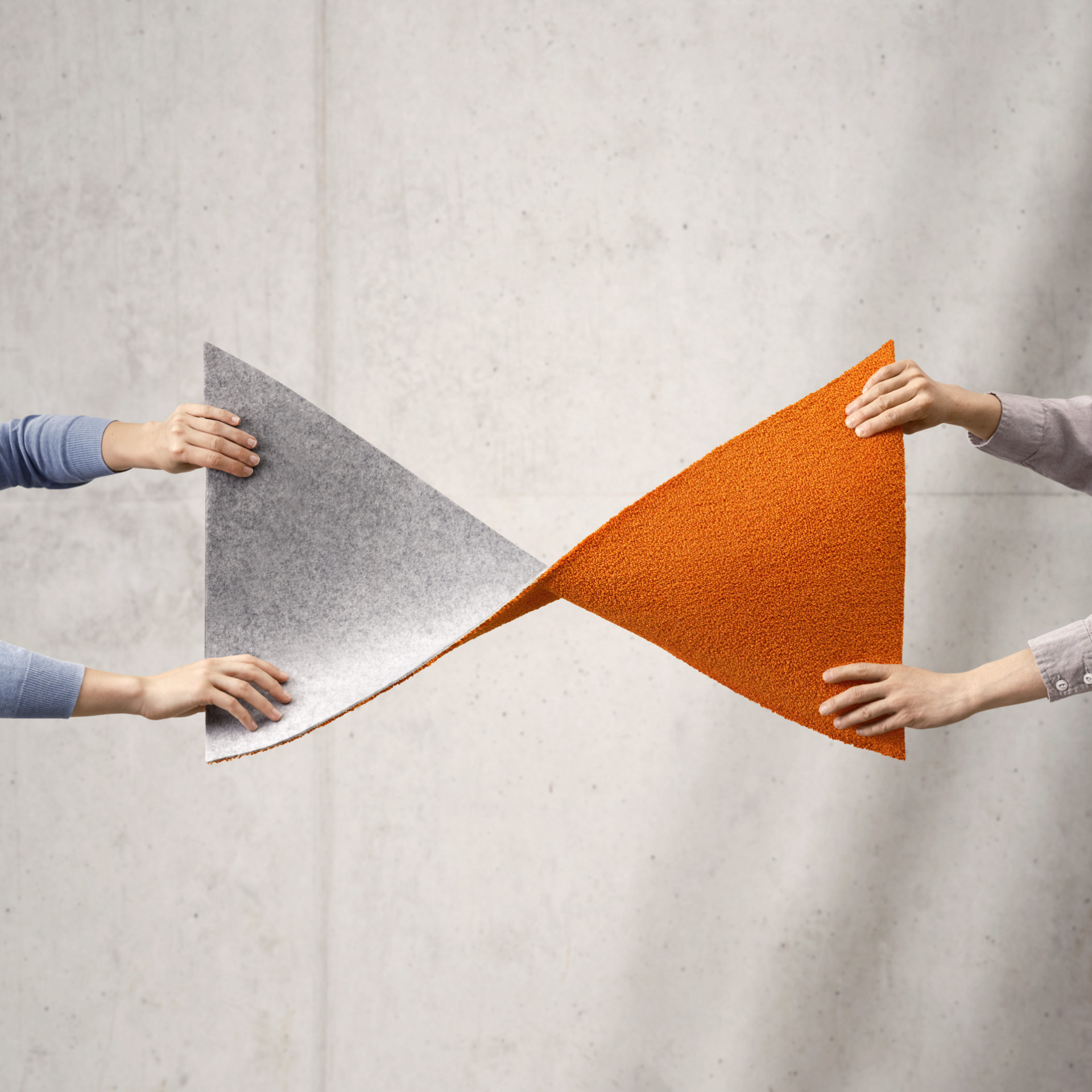

We're better together

How we collaborate

Stories

|

Many products contain materials that are not reusable, renewable or recyclable. The good news is that awareness is growing that such materials are unfit for the circular economy. But, what probably stands in the way of repair, reuse and recycling the most, is the fact that nearly all products are designed in such a way that materials are fixed together for eternity. This means that, even if products are designed with materials that are reusable or recyclable, they will still be trashed at end of a product’s use. Simply because the materials cannot be separated one from the other. Over time, we learned that, we need to radically change the way in which we design products. Instead of designing a product – and choosing materials – solely based on a product’s use case and production costs, we need to also look at what makes a product fit for repair, reuse or recycling in an economically feasible manner. We need product design that’s fit for a circular economy. |

|

It’s what we call ‘designing with the end in mind’: so that nothing ends up as waste at the end of use. These are the three design principles are key to enabling such change:

Our radical approach to product design also brought with it the opportunity to rethink manufacturing technologies. In the case of carpet manufacturing, we were able to cut back energy consumption by a staggering 90% and no water is needed anymore. What’s more, instead of using gas, the carpet line runs on renewable energy.

The carpet manufacturing environment has also become uniquely healthy now that the Volatile Organic Compounds (VOC’s) and substances of concern – used in traditional carpets – are no longer necessary thanks to redesigning for circularity.

|

‘’ -

“When challenged to redesign carpet from scratch and develop a mono-polyester carpet, we even needed to wholly engineer a polyester hotmelt adhesive. In the end we managed to make it tick all the boxes. The click-unclick polyester adhesive we developed is clean, reversible and recyclable and enables separating materials for high quality reuse or recycling in their own material stream. The next innovation was that we could also use it to redesign other applications from scratch like mattresses and panels.” |